Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

Packaging Innovations & Empack 2026 puts sustainability and circular solutions in the spotlight

Day two of the UK’s leading packaging event drew hundreds of top brands, showcased cutting-edge sustainability innovations, and provided key insights ahead of the UK’s 2027 deposit return scheme launch.

Day two of Packaging Innovations & Empack 2026 reinforced the UK packaging industry’s sense of momentum, marking a record-breaking edition that attracted hundreds of leading brands and generated overwhelmingly positive feedback from exhibitors and visitors alike.

Sustainability took centre stage, with circular design innovations, data-driven recyclability solutions, and creative packaging approaches on full display. From peel-and-reveal labels to marine-recovered recycled materials, the event highlighted how collaboration, operational excellence, and forward-thinking design are converging to shape a more circular, sustainable future for UK packaging.

The show’s timing also coincided with the UK preparing to roll out its landmark deposit return scheme in October 2027, designed to transform how containers are collected and recycled. Drawing on lessons from early adopters such as Ireland and Scotland, the scheme has already revealed practical insights and potential challenges.

Julian Hunt, Director of Exchange for Change, took to the Circular Economy Stage to emphasise the importance of industry leadership in making the scheme successful: “If this scheme is to deliver effectively within the framework of effective EPR, it has to be run by industry. We were very clear from day one this has to be by industry, for industry, to ensure that industry delivers on its legal obligations but delivers it in a way that works for consumers, and critically of course, works for the planet and delivers the outcomes that we all want to see from a deposit return scheme.”

Building on that principle, careful operational planning is essential. Sarah Horner, Director – UK & Ireland at Reloop, explained the lessons learned from Scotland: “We analysed what Circularity Scotland (CSL) did there and they basically had too many return points. So when we were drafting the legislation, the reason we put in boundaries around return points is because there were three times as many as needed in Scotland and that’s an added cost. We’ve given some guidelines in the legislation to the DMO, but there’s an onus on them to review that and make sure they’re sufficient. So, we really thought that through.”

Lessons were also learned from Ireland, where early implementation has helped build momentum and provided practical insights for the UK. Ensuring the system succeeds requires close collaboration between industry, government, and consumer engagement, with detailed planning to make the scheme operational from day one. The impact of such a system is already evident: Ciaran Hope, Chief Operating Officer for Re-turn, highlights that, “We do a coastal survey around the country every year and they survey 500-550 sites. On average it used to find 100–110 containers per kilometre. Last year they did that survey and it was down to about five – it was the lowest in a quarter of a century.

“In less than a year, we’ve wiped out all material that existed in rivers and seas.”

Industry advisors behind PackUK are taking a central role in shaping the future of pEPR, ensuring that the packaging value chain is aligned on both strategy and practical delivery. John Coates, Policy and External Affairs Manager at PackUK and Re-Gen Waste, explained the scale and complexity involved: “There’s four nations, so there’s four parliaments that you’ve got to work with. And beneath those four parliaments, there are 400 varieties of council and then many hundreds of thousands of producers sitting on top of that.”

He highlighted the need for producers to understand the intricate operations of local authorities, from collection contracts to post-use sorting and reprocessing, and noted that PackUK provides a central communication channel to coordinate these interactions effectively.

Turning to the technical levers driving industry change, Emma Wilkinson, chair of PackUK’s Recyclability Assessment Methodology (RAM) Technical Advisory Group, underlined the importance of correct interpretation of RAM for producers: “If producers that are working through their RAM assessments can speak to other people in the space, lean on PackUK if they’re unsure of anything, to make sure that they’re interpreting it in the correct way, I think at this stage, that’s a really important factor.”

Panel Chair and Chief Strategy Officer at PackUK, Esther Carter, explained the role of RAM modulation in incentivising better packaging design: “Red this year is going to be 20% more expensive than the base, or what’s now referred to as the amber fees, and that additional money raised will be used to discount the green fees. It’s about getting the right balance between incentivising the right things and working very closely across industry material specialist groups to try and get that right.”

Supporting legislative and regulatory changes, innovation across the packaging value chain demonstrating how designs, materials, and technologies are being rethought for a more circular future. Megan Hinkley, Senior Product Manager – Packaging at Innovia Films, explained: “Because we operate across multiple extrusion technologies – Cast, LISIM®, Stenter and Bubble – and have in-group metallising and AlOx coating capabilities, we can combine those in different ways to create modern, recyclable mono-material solutions. Everything we manufacture is designed for recycling and aligned with PPWR, and we’re able to incorporate recycled content too, whether that’s mechanical, ISCC-certified chemically recycled, or bio-circular material. One of our newest innovations is incorporating food-contact approved, mechanically recycled ocean-bound plastic into flexible films. This is something we’re uniquely positioned to do. Ultimately, if someone walks onto the stand, the message is simple: we can replace traditional multi-material structures like PET/foil laminates with fully polypropylene alternatives that maintain performance while improving recyclability and future compliance.”

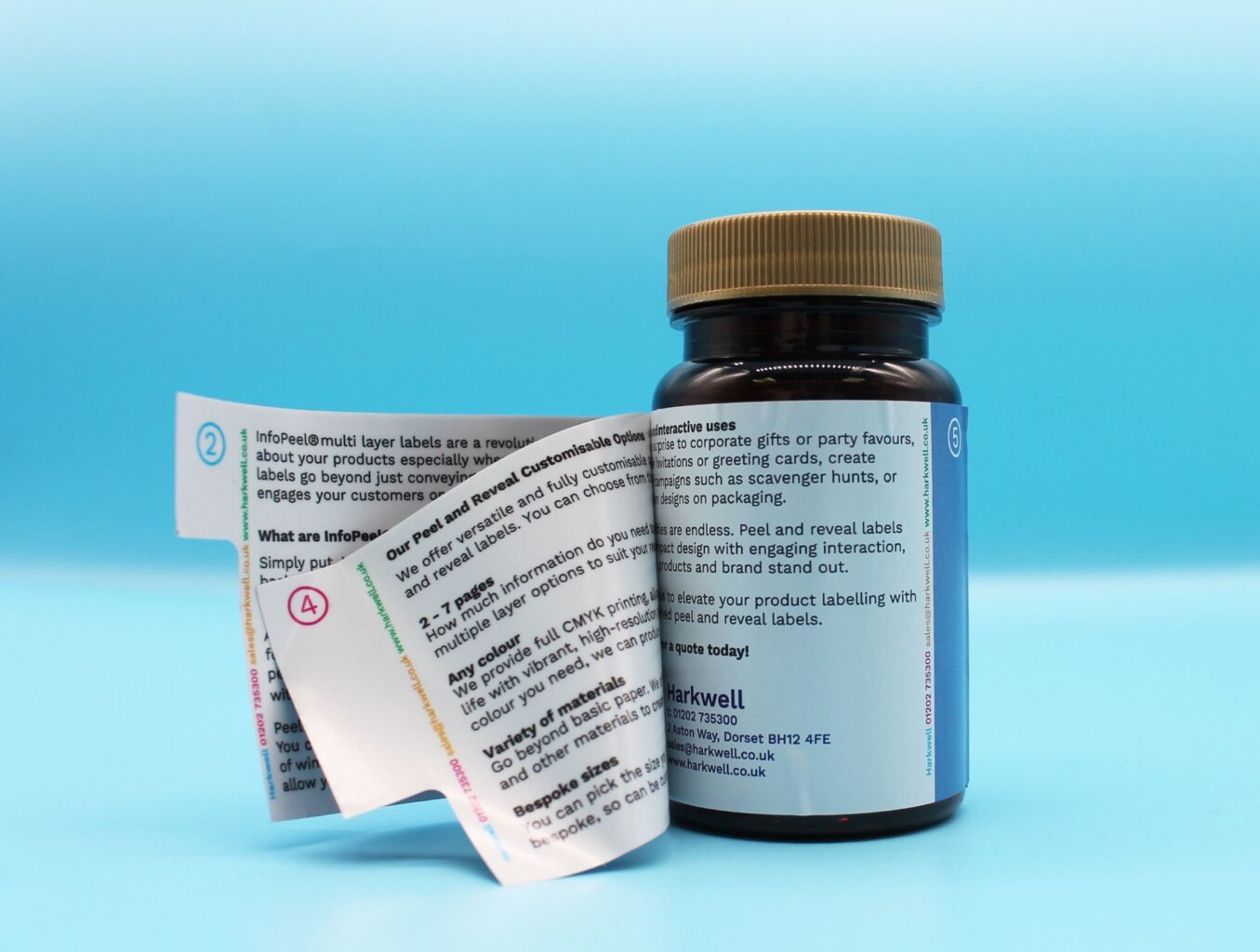

Andrew Mansfield, Managing Director of Harkwell Labels, highlighted how innovation in label design is reshaping the way consumers engage with packaging information. His team has focused on creating interactive, multi-layered solutions that balance functionality with storytelling, making complex product information accessible without compromising the visual appeal of the pack.

Mansfield explained: “InfoPeel™ and our tabulated peel & reveal range were designed to rethink how consumers interact with packaging information. The concertina on top, for small beauty jars, opens easily to reveal multiple areas of information, while wraparound labels cover 360 degrees, and multi-page tabulated layouts allow layers to be peeled back simply. With high-definition print, metallics, and multi-colour digital capabilities, brands can tell a story, show multiple languages, or highlight product details without cluttering prime pack space.

“The response has been immediate, with sample packs flying off shelves, and brands recognising how much easier and more appealing the peel & reveal experience is.”

The GrabLok™ linerless tamper-evident bag closure developed by Westpak Group was named the winner of the Innovation Gallery for its simple but powerful rethink of takeaway security. Designed to help QSR brands prevent open bag complaints, reduce refunds. and protect order integrity from kitchen to customer, the linerless closure seals delivery bags quickly, cleanly and with minimal waste.

Paul Magee, Sales Director at Westpak Group, said: “There was a big, steep incline in the home delivery food market, but packaging never actually developed fast enough to keep up with that, so that’s what we’ve done and brought a full range of products.

“The GrabLok™ concept is a linerless label, so there’s no backing paper. Backing paper is not recyclable, it’s not compostable, it’s not good for the environment, and it’s also less efficient. GrabLok™ goes straight off the bag, it’s peel-and-reseal, it’s tamper-evident, it keeps the food clean and safe and warm in a very clean-looking way, and it’s faster to operate in store as well as being very environmentally friendly.”

Brendon Bale, Stakeholder Manager at Prevented Ocean Plastic, whose first ever food-safe recycled polypropylene (PP) claimed second prize in the Innovation Gallery, said: “The last couple of days at Packaging Innovations with Prevented Ocean Plastic have been super, super strong. We engaged with a broad range of direct plastic manufacturers. We also had conversations with brands including Highland Spring, Müller, Pringles, and others. There have been too many positive conversations with inspiring people to count!”

Greyparrot, whose founder, Yaseed Chaumoo, was named Packaging MVP in the Future Trailblazer Awards on Day 1, is transforming how brands understand their packaging in the real world. Chaumoo explained: “We now capture around 1.5 billion waste objects a day across 20 countries, so if it’s sold in a supermarket, we’re probably seeing it somewhere in the system. That data helps facilities improve efficiency, reduce contamination and even identify batteries before they cause fires, but the real value for brands is insight and prediction: we can show how your packaging is actually performing in the real world, how it benchmarks against your category, and then model ‘what if’ scenarios; what happens if you remove a sleeve, reduce it by 10-40%, or redesign a component.

“Instead of guessing, you’re making data-led decisions that improve recoverability, protect brand identity and potentially reduce future EPR costs, effectively closing the loop between design, regulation, and real-world recycling performance,” stated Chaumoo.

Thomas Glendinning, Managing Director of Sovereign Labelling Machines, said: “There’s a unique buzz that we get here. We’re speaking to the right kind of people, and we’ve had a really strong level of interest in the machines. The Empack portion of the show is growing in prominence and importance, and people are now very aware it’s not just packaging here, it’s machinery too, so we’re very happy overall.”

Austin Schwarz, Trays Regional Sales Director UK&I at Klöckner Pentaplast (kp), said: “It’s our first show here with KP. We’re super pleased and it’s incredibly well organised. We’ve been speaking with some really good potential customers, and it was great to catch up with some existing customers. We’ll definitely be back again next year.”

Event organisers Easyfairs are set to reveal official attendance figures in the coming days, but with hundreds of leading brands and overwhelmingly positive feedback from exhibitors and visitors alike, Packaging Innovations & Empack 2026 has already marked itself as a standout edition.

Attention now turns to London Packaging Week, taking place at the Excel London on 16 & 17 September, which delivers cutting-edge insight into the trends and challenges shaping the packaging industry, as well as the latest innovations, sustainability solutions, and collaborative opportunities driving its future.

Share this article

Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.