Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

How Greyparrot’s Deepnest is turning post-consumption reality into packaging intelligence

For decades, packaging innovation has focused almost exclusively on driving sales, boosting shelf impact, brand recognition, and optimising convenience and cost. What happens after consumption, once packaging slips from the consumer’s hand into the waste stream, has remained largely abstract. Assumed. Modelled. Estimated. Rarely observed at scale. That abstraction ends in 2026, the first year in which packaging performance at the sorting line begins to show up directly on brand P&Ls. Greyparrot’s team believes that waste data is needed to help those brands adapt.

Deepnest, the latest evolution of Greyparrot’s AI-powered waste analytics platform, is built on a simple yet radical premise: if packaging performance is measured with recovery rates, then brands need to understand what actually happens to their products after disposal– not what was intended at the design stage. With the rollout of Extended Producer Responsibility (EPR) in the UK and the Packaging and Packaging Waste Regulation (PPWR) in the EU, compliance fees will be linked to how products behave in real waste systems – not whether they are theoretically recyclable. Formats will fall into green, amber, or red fee bands, directly affecting the cost of bringing products to market.

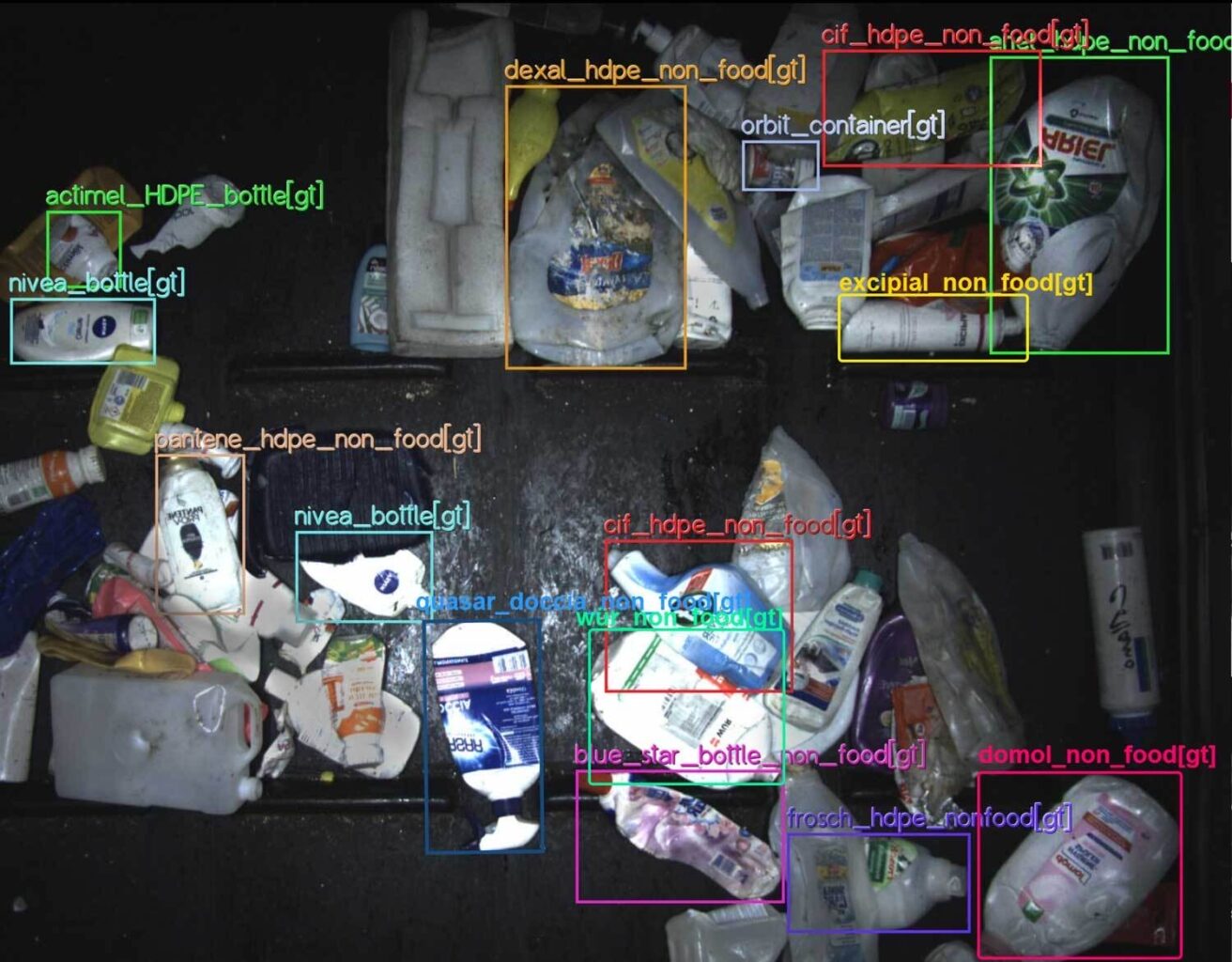

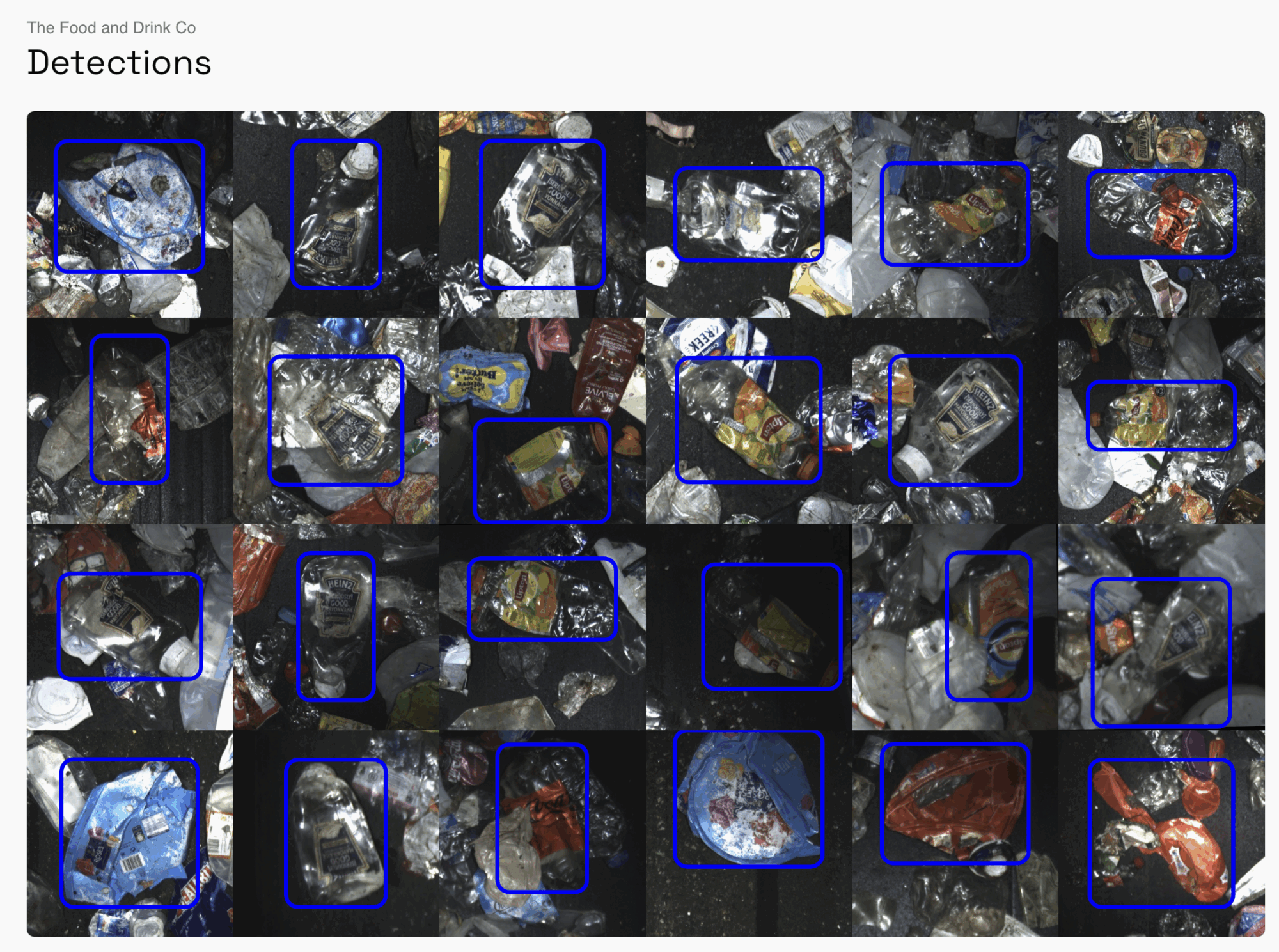

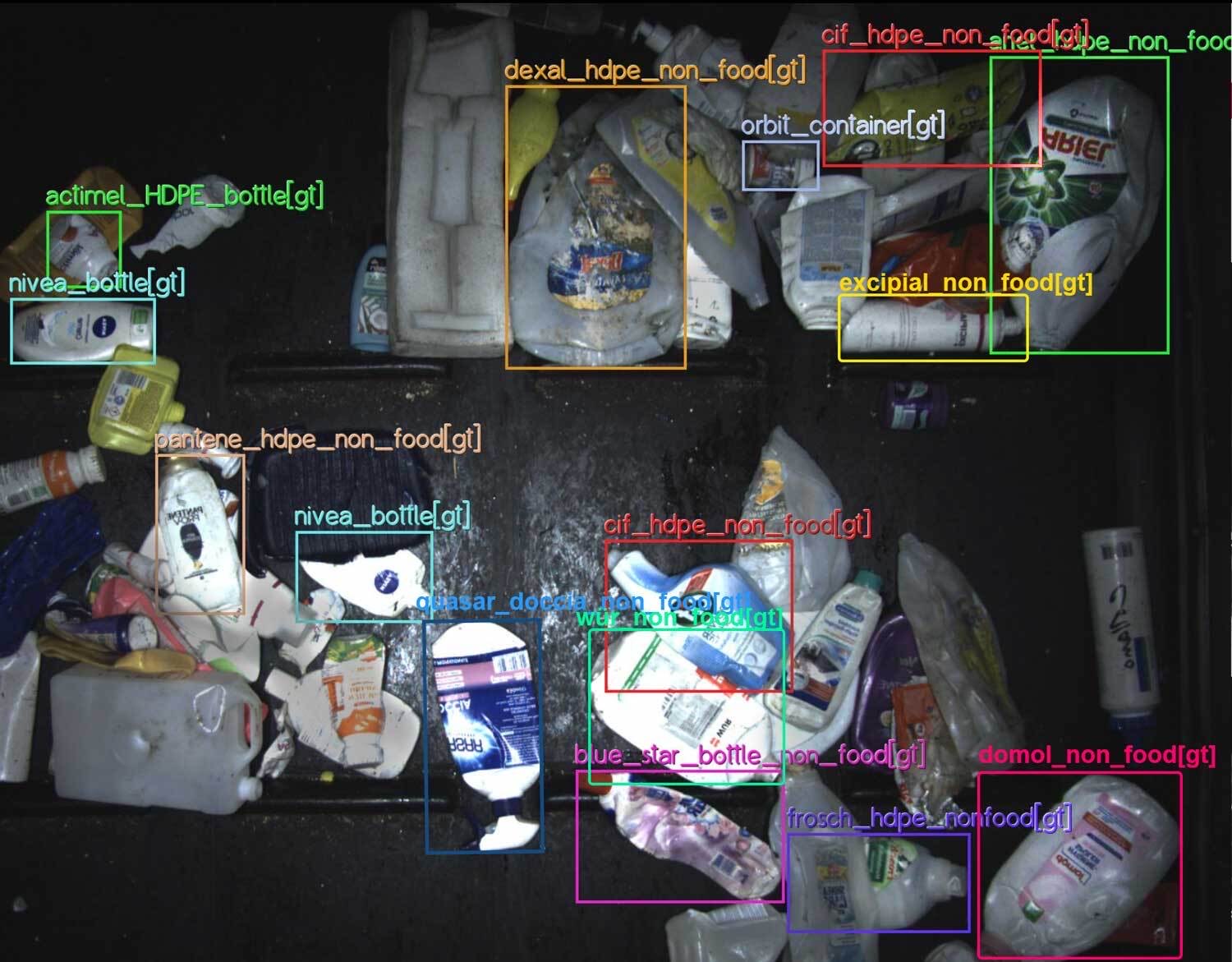

Positioned on moving conveyor belts, Deepnest uses computer vision and artificial intelligence to identify real products, not just material categories, as they move through global recycling plants. In doing so, it exposes the reality gap between packaging design and packaging outcome, definitively answering questions that determine a product’s fate. Which formats are correctly identified? Which colours fall out of the system? Which labels, pigments or component choices quietly derail recyclability at scale? The data shows that nearly one in five packaging items still fail to enter a recyclable output stream, despite design intent. “We effectively see everything that’s sold in a supermarket,” explains Yaseed Chaumoo, Managing Director at Greyparrot. “Recyclable or not – we see everything that goes through the recycling system.”

That visibility is what makes Deepnest different. The platform doesn’t speculate about recyclability – it quantifies real recovery rates. That insight is reshaping how brands, waste operators and regulators think about responsibility, performance and value at the end of the line at a critical moment. Poor performance will no longer be absorbed quietly by the system, but reflected in modulated fees, higher costs and competitive disadvantage.

From waste analytics to packaging intelligence

Greyparrot was founded six years ago with a mission to turn waste from an operational cost into a recoverable resource and accelerate the transition to a circular economy. Built by a team with deep roots in AI and decades of experience deploying computer vision systems globally, the company developed AI-powered Analyzer units – camera hardware installed above sorting lines that observe and classify every item moving through a facility.

“The way I frame it,” says Yaseed, “is that facilities have eyes, brains and limbs. We’re the eyes and brains – observing every object, and identifying what each item actually is.”

Greyparrot’s technology has helped waste operators across 20 countries understand loss points, material leakage and operational inefficiencies at unprecedented scale. In 2025 alone, Greyparrot’s AI analysed 43.5 billion individual packaging items moving through real sorting plants – creating what is arguably largest dataset of packaging recoverability in existence. Deepnest sharpens that focus for brands, identifying specific products down to the SKU level.

The simple question which sparked Deepnest’s development was: if AI can identify polymers, shapes and materials, can it also recognise specific products and the brands behind them? Not via logos alone, but through the full visual fingerprint of packaging – colour, geometry, texture, and format.

“The model works like face recognition on your phone,” Yaseed explains. “It clusters what it sees and asks, ‘Who is this?’ Then we label it.”

That capability transforms waste data into something far more powerful: packaging waste intelligence.

Designing from reality, not assumptions

For consumer brands navigating EPR and PPWR (and preparing for modulated fees), Deepnest arrives at a critical moment. Regulation has moved from abstract policy to material financial pressure, and many of the assumptions underpinning recyclability no longer hold up under real-world scrutiny.

“There are design-for-recyclability standards, and they’re not wrong,” says Yaseed. “But brands can’t just adopt them wholesale. If everyone uses the same materials, colours and formats, everything looks the same. Brand visibility collapses. It’s a balancing act.”

Deepnest is designed to support that balance, not by prescribing a single “correct” solution, but by revealing how specific design choices behave across markets, facilities, and infrastructures.

The platform’s first core capability is baseline performance: measuring where products end up, whether they are correctly sorted, misidentified, or lost to residue. Across billions of observations, the worst performers are often formats that brands already suspect, but have struggled to quantify. Black plastics, metallised films, EPS, and low-grade fibres are difficult to sort, while clear PET bottles, white dairy tubs, corrugated board, and aluminium consistently deliver high capture rates and clean material streams. But the real value emerges when brands begin to model change.

“We can say, if you make this colour change, this is what will happen,” Yaseed explains. “If you adjust opacity, pigment or format, this is how it’s likely to behave, because we’re modelling it against a wide, real dataset.”

That ability reframes packaging development from trial-and-error to an informed roadmap. With 2030 targets looming and packaging decisions often locked in years in advance, predictive insight becomes essential rather than optional. In categories like health and personal care – where sachets, pumps, tubes and shrink-wrapped formats dominate – Greyparrot’s work with leading brands shows that many ‘recyclable’ designs underperform once they hit the sorting line, placing significant portions of today’s portfolios on course for the red end of modulated fee scales in 2026.

“Mould choices can take two years. Pigments can take six months,” Yaseed notes. “If you’re working towards 2030, you need to be making decisions now.”

Beyond compliance: Data as a shared language

While Deepnest is already proving its value to packaging teams at L’Oreal, Unilever and Amcor, its longer-term implications extend well beyond corporate packaging teams. One of the most significant opportunities lies in how post-consumption data could reshape the relationships between brands, PROs, and regulators.

Today, many EPR and fee modulation frameworks are built on simulation and modelling. Deepnest offers something different: near real-time, facility-level evidence of recoverability across diverse infrastructures. For the first time, it’s possible to answer questions such as: “What happens to our EPR bill, and our effective packaging margin, if we redesign 10%, 20% or 30% of our portfolio for real-world sortability?”

“It’s probably the most comprehensive packaging data system that exists,” says Yaseed. “And it takes into account the fact that facilities are different – five-year-old infrastructure versus brand new, different configurations, different regions.”

In time, that evidence could inform fairer, more accurate fee structures, aligning financial incentives directly with real-world performance rather than theoretical design intent.

“If PROs use this data, and brands know what PROs are seeing, you create alignment instead of contradiction.”

Systems, not slogans

That philosophy is central to Yaseed’s thinking. Having advised the World Health Organisation on global health data platforms, and previously co-founded and exited an AI SaaS company acquired by a FTSE 250 firm, he’s spent his career turning complex data into decisions. It’s also why he’s sceptical of anything built on slogans rather than systems grounded in reality.

“It’s very easy to say brands should ‘just do it, ’” he says. “But CPGs operate in complex matrix organisations. If you don’t understand their processes, you can’t drive real change.”

Instead, he sees sustainable packaging as a managed, incremental, data-led, and consumer-aware transition – a lesson reinforced by high-profile failures and quieter successes alike.

“If you make a dramatic change, consumers don’t like it,” he notes. “But with gradual experimentation, people adapt. Look at how formats like confectionery tubs have evolved.”

Taking the conversation to Packaging Innovations & Empack 2026

This systems-level thinking will be front and centre when Yaseed takes the stage at Packaging Innovations & Empack 2026, contributing to two sessions that reflect Deepnest’s growing role across the value chain.

On Wednesday, 11 February, he will introduce the platform directly in “AI-driven packaging waste intelligence to boost recycling and cut EPR costs”, outlining how brands can move from compliance anxiety to confident, data-backed decision-making.

The following day, Thursday 12 February, Yaseed joins a cross-sector panel alongside Biffa and Sherbourne Recycling for “Connecting the value chain: technologies at the sorting line helping to close the recycling loop”, a conversation that situates Deepnest not as a standalone solution, but as connective infrastructure between design, disposal and recovery.

It’s a fitting platform for the technology, and for its advocate.

Deepnest is not about perfect packaging, but honest packaging. Deepnest reveals what happens when intention meets infrastructure, giving brands the clarity they need to design not just for the shelf, but for the system their products ultimately enter.

As Yaseed puts it, “The ultimate goal is to use this treasure trove of data to drive real change – and then watch it have the impact it’s meant to have.”

Share this article

Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.