Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

When constraints spark creativity: Jude Pullen on the future of packaging

Innovation often begins in the spaces between expectation and possibility, in the quiet moments when the familiar begins to reveal its limits. A box that resists opening, a shipment that wastes space, or a regulation that feels constraining; these are not mere inconveniences but invitations to rethink, reimagine, and reinvent. For Jude Pullen, renowned Creative Technologist, these moments are the genesis of creativity. They are the precise conditions in which imagination, technical insight, and hands-on experimentation converge.

At first glance, packaging may be seen by many as a simple interface between product and consumer. Yet Jude sees the hidden potential in every crease, fold, and material choice. He describes how small ergonomic insights can lead to disproportionately large improvements. Constraints placed on the design of packaging, in particular, are opportunities for creative breakthrough. “A seemingly left-field design brief could be to explore if something can be operated single-handed: That insight may open up all sorts of secondary benefits. Most people take it for granted that they’ll use both hands to open packaging, but designing something that genuinely works single-handedly is actually quite a skill. For example the Fed-Ex ‘tear strip’ is an iconic example. I really enjoy creative challenges like that – not because the majority of people only have the use of one hand, but because often we are multi-tasking – an obvious example is that you can text single-handedly on a smartphone – which is by design – and a notable change from the BlackBerry keyboard on early smart-devices” What begins as an adjustment to the way a hand interacts with a lid can ripple outward, informing considerations of efficiency, accessibility, and overall user experience.

Over the past six years, Jude has repeatedly been brought into projects where conventional thinking has stalled, often involving unusual briefs, tight timelines, or internal teams stretched thin. In these moments, his value emerges not from inventing entirely new knowledge, but from surfacing the knowledge that already exists. “More often than not, all the knowledge already exists inside the company; my job is to extract it and make it engaging and useful. What’s often missing is creative bandwidth, the space to step back and re-evaluate assumptions about user experience or, increasingly, legislation.” Through this lens, curiosity meets constraint, yielding solutions that are both practical and imaginative.

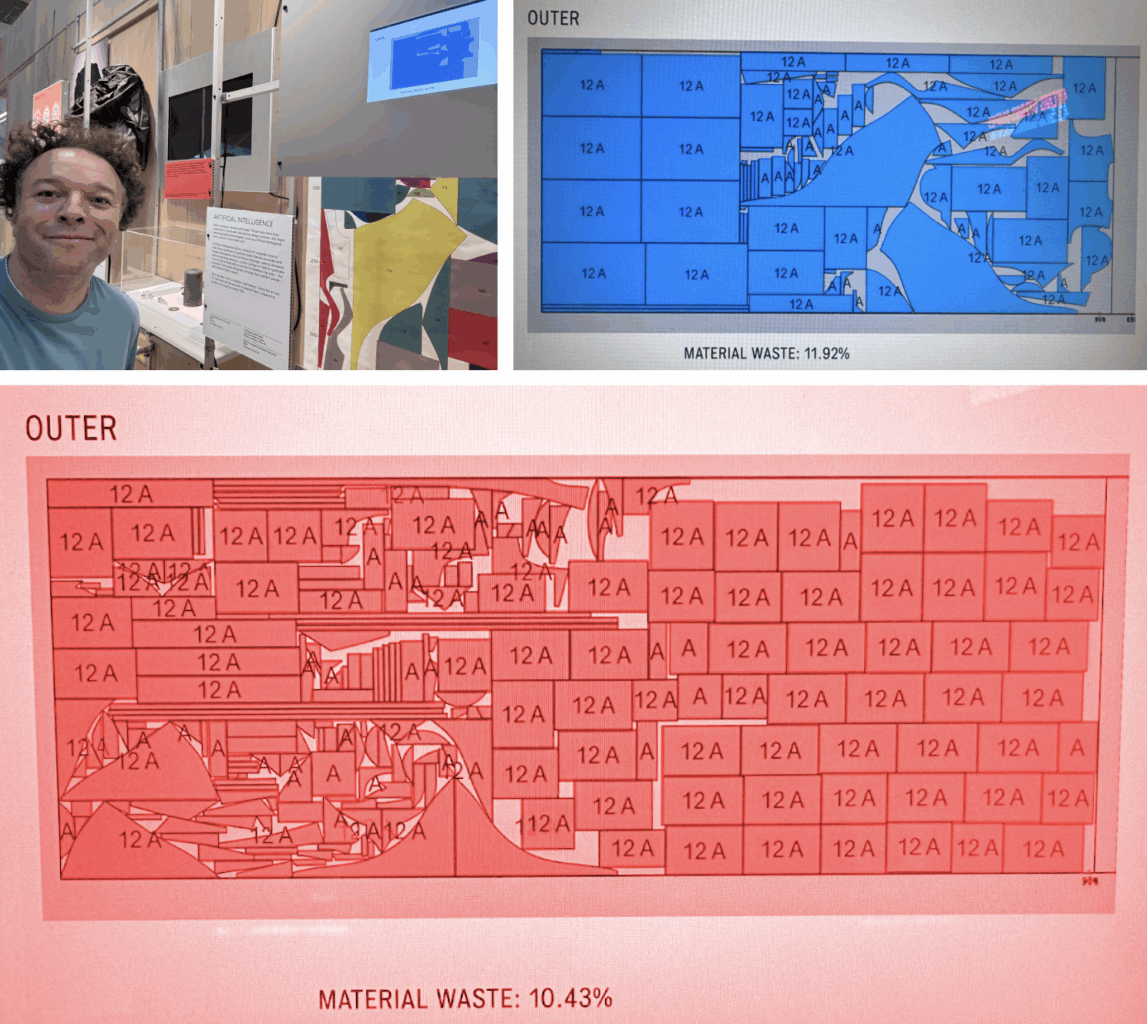

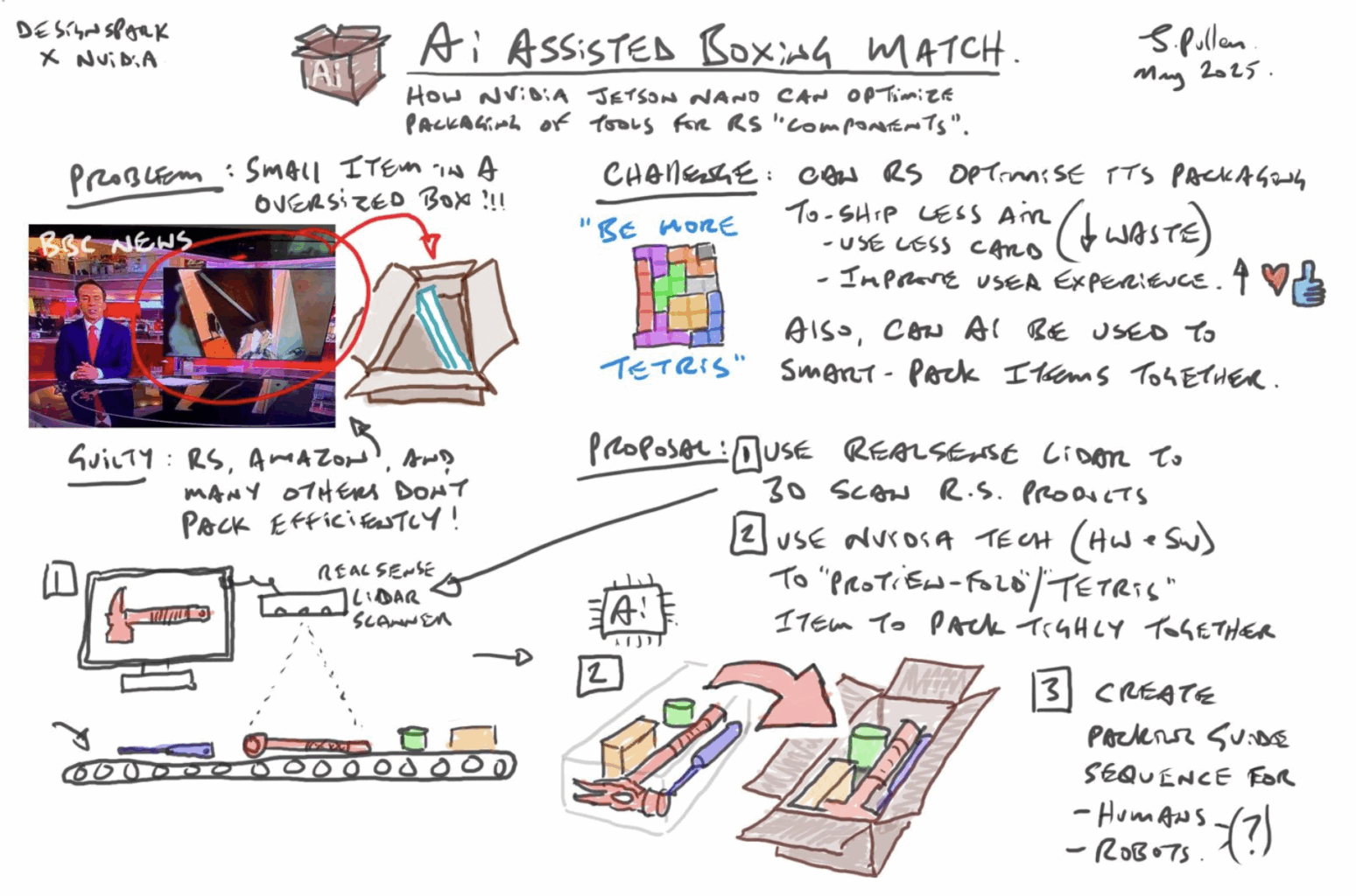

It is this mindset that he brings to Packaging Innovations & Empack 2026 in his session, “Creativity in constraint: How to stay bold when regulations, markets & money push back.” Attendees will explore how regulatory, logistical, and financial pressures – often perceived as obstacles – can actually catalyse invention. Jude’s approach blends analytical rigour, hands-on prototyping, and the capacity to experiment under real-world pressures, demonstrating how creativity thrives when options feel limited. He cites work from his favourite biscuit packaging, to his recent work with multinational electronic distributor, RS, in collaboration with NVIDIA – using AI to explore more sustainable, and more economical packaging solutions.

Optimising the awkward

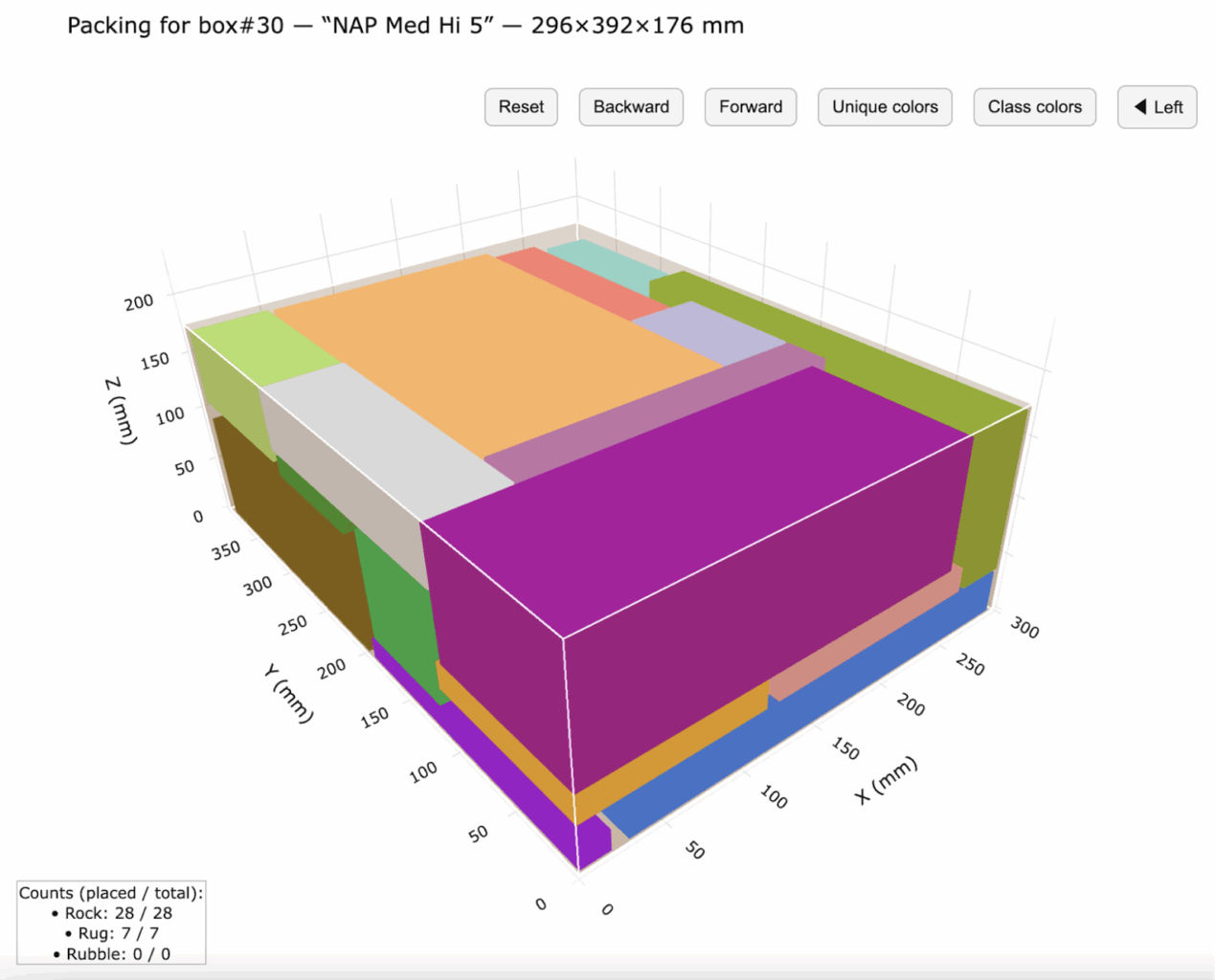

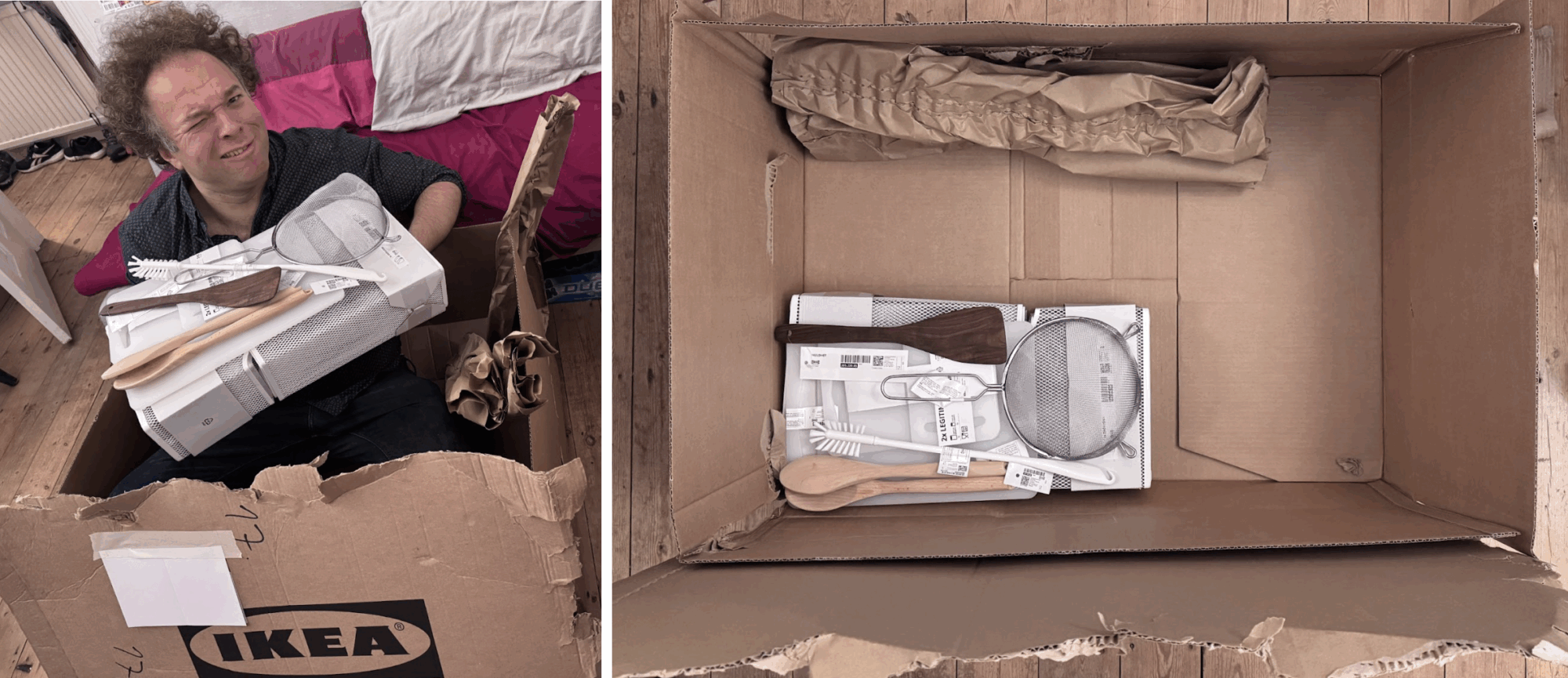

One recent project, dubbed “The AI Boxing Challenge”, illustrates this philosophy vividly. Observing small products shipped in disproportionately large boxes, Jude began exploring more intelligent ways to pack items. “Almost like Tetris. Mathematically, the ideal outcome would be perfect tessellation, but that’s rarely achievable in the real world. You don’t always have shapes that fit neatly together, and computationally, it’s very complex. The real question isn’t whether we can achieve perfection, but whether we can do better than what we’re doing now.” In this case, the act of shipping became a playground for problem-solving, where logic, mathematics, and human intuition intersect to transform a seemingly mundane task into an arena for innovation.

Constraints are rarely purely technical. Regulation shapes opportunity as much as it sets boundaries. The PPWR, which limits void fill to 50% (with some EU countries pushing toward 40%), creates pressure for more thoughtful and optimal packing. “When you look at current packaging through that lens, a lot of it looks pretty bad. But it’s also not trivial. How do you ship something like a tennis racket or a hammer efficiently? These awkward objects force you to think differently. Our approach has been to ask what sits between those extremes, and how algorithms can help us find smarter compromises.” Jude’s work demonstrates how regulatory frameworks can become design prompts rather than restrictions, forcing creative thinking that respects both physical realities and legislative intent.

Even sophisticated technological systems rely on human insight. “A hammer shouldn’t ship alongside light bulbs. But you can imagine an AI system trained to infer those relationships by understanding product descriptions, categorising items as heavy, fragile, compressible, and so on. With appropriate human oversight, AI can make reasonable inferences that reduce damage and waste.” In this way, technology becomes an amplifier of human thought, enabling smarter decisions while freeing designers to focus on judgement and nuance that machines alone cannot replicate.

Time, like space, imposes constraints. “We’ve developed an algorithm that performs intelligent sorting, but we’re very clear that optimisation has limits. For a company shipping thousands of orders a day, spending twenty minutes packing one box perfectly makes no sense. Sometimes two boxes are cheaper and better than one ‘perfect’ box. Optimisation isn’t just spatial, it’s temporal. You can’t treat logistics like a jigsaw puzzle when throughput is the singular priority. But that doesn’t mean there aren’t opportunities for improvement. Even small nudges can make a difference to the planet and to profits.”

Rethinking packaging from the inside out

Some of Jude’s projects are particularly revealing of how design, logistics, and technical ingenuity intersect. At Dyson, there was a brief asking whether a vacuum cleaner could fit onto the profile of an A3 sheet of paper. The challenge combined product design with shipping and logistics, forcing innovative thinking about telescopic handles, modular sections, and avoiding “wonky or overly elaborate” mechanisms. Similarly, at RS, he explored how automated packing equipment could be paired with subtle behavioural nudges – such as small discounts or visual cues – to reduce waste and improve efficiency without overcomplicating operations. These are explored in his 6-part blog series for RS and NVIDIA, on RS DesignSpark (Search “Jude Pullen”).

Packaging is not only a matter of function; it also carries the potential for experience, delight, and imagination. “I once noticed how much printing Amazon includes inside its boxes and wondered whether that surface could be repurposed creatively. What if it became something playful or reusable, especially for children? A QR code linking to ideas for reusing the box, for example. These ideas might sound ‘non-critical’ or idealistic, but I’ve learned that sometimes, for the right brand and consumer story, you catch the right wave and an idea gains traction.”

The impact of thoughtful packaging extends far beyond immediate projects. “You can work on projects that feel meaningless, where the outcome doesn’t really matter. But if you can reduce packaging by even five or ten percent at scale, the impact is enormous, both financially and environmentally.” Even proposals that didn’t go the full distance, like redesigning McDonald’s Happy Meal packaging, shaped his thinking. Jude reflects on the ethical dimension: he wouldn’t help a company create more unnecessary plastic, but engaging with those genuinely committed to reducing their environmental impact allows him to make meaningful, pragmatic contributions, even in industries often perceived as problematic.

Looking toward 2030 sustainability targets, Jude stresses the need for early action: “Most companies need two to three years for R&D, approvals, and rollout. If you want to hit 2030 goals, you really need to be starting now. That means designing sustainability in from day one, not bolting it on at the end.” Legislation, he explains, can be more than a challenge; it can be a source of invention. “Anything oddly shaped becomes a challenge under void-fill limits, and that pressure can drive genuinely innovative thinking. There may be some gaming of the system, but I’d rather be on the side that embraces the spirit of the regulation and does a good job.”

The stakes are high, but so is the opportunity. Packaging may lack some of the glamour of product design, yet its influence is profound. LEGO’s move from plastic to paper bags “wasn’t trivial; the paper had to be strong enough to survive production without tearing. Every change involves trade-offs, and you can’t optimise using a single metric like CO₂ alone. Sustainability is inherently multi-dimensional. That complexity is what excites me. It’s about balance.”

Augmenting human ingenuity with AI and automation

AI and automation open new avenues for efficiency and precision. “Many operations teams think they have no slack, but when you look at the full workflow, from order placement to packing, there’s often plenty of computational downtime. That’s where AI can work in parallel, optimising decisions before a human even touches the box. Even simple interventions can help, like printing the recommended box size on a packing slip. Automation should take on dull, dangerous, dirty, or difficult tasks, (aka ‘The 4 Ds’), leaving humans with the interesting work.”

From condoms to pyramid tea bags, Jude’s eclectic range of clients and projects has explored packaging at its most intricate. “Sometimes people make mistakes not because they’re careless, but because they’re under pressure. Pick-and-place robotics, for example, is far more complex than people realise, especially when ad-hoc judgement is required. Packaging problems often look trivial from the outside, but once you understand the mechanics, they’re fascinating. Packaging can have surprising side effects, and sometimes those stories resonate more than highly polished marketing narratives.”

Even in testing ideas publicly, Jude demonstrates his methodical approach. “I use platforms like LinkedIn to test ideas, much like comedians testing jokes. It’s a low-risk way to see what resonates before developing something more substantial. Often the message or story can be as critical as the innovation itself, as many brands are aware.”

Ultimately, he sees the present moment as one of enormous opportunity. “Legislation is forcing change, but that pressure creates opportunity. The work I’m doing now is good for the planet, but it’s also good for profits. Shipping smaller boxes is objectively better for business and the environment – and that story of ‘doing both’ is what is critical as companies want to be greener, but also survive the economic pressures of late. I look for the win-win.”

And the reward, he concludes, is tangible: “Staff engagement improves when ESG goals are tangible. Waste reduction directly supports profitability. And marketing teams gain something real to talk about, rather than having to spin vague claims. Consumers, at worst, are indifferent; at best, they respect companies that take sustainability seriously. This isn’t something to panic about. It’s achievable, practical, and worth doing.”

Check out Jude Pullen’s blog series on DesignSpark, and join him and over 80 industry-leading speakers to explore the future of packaging innovation, sustainability, and applied technology. Across two days at the NEC Birmingham, discover practical insights, bold ideas, and real-world solutions alongside 450+ suppliers, 7,400+ visitors, and 3,000+ brands shaping the industry.

Register now for your complimentary ticket to Packaging Innovations & Empack 2026, 11 & 12 February, and see how creativity thrives in constraint.

Share this article

Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.