Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

Stand up for pouches, lay down for packs

Form-Fill-Seal systems automate the packing process of dry, solid and powdered goods, increase throughput, and deliver consistent pack performance.

While the use of horizontal (HFFS) and vertical (VFFS) systems varies depending on the product and application, both are core processes in the supply chain and will be demonstrated in depth at Packaging Innovations & Empack 2026.

Horizontal Form-Fill-Seal (HFFS) and Vertical Form-Fill-Seal (VFFS) machines are essential in modern packaging and vital for high-volume industries such as protein, snacks, confectionery, personal care, and pharmaceuticals.

Both types of Form-Fill-Seal (FFS) system automate the entire packing process by forming the pack, filling it with the product, and then sealing it ready for distribution and retailing.

HFFS excels with solid, rigid, or irregularly shaped items, such as chocolate bars, wet wipes, and medical devices, and works well for flow-wrapped products.

VFFS meanwhile, is best suited to free-flowing or granular items (snacks, coffee, powders, rice) and can form pouches in many different formats.

The depth and breadth of FFS will be on show at Packaging Innovation & Empack 2026, where the materials and the machines will be presented for all those contract packers and manufacturers looking to enhance their production capabilities.

Pack to the future

A100 from AutoPack (V132) is a compact and easy to use VFFS machine that offers a low cost of ownership. A100 can be used semi automatically by hand feeding products into the top or coupled with automatic filling machinery such as weighers, augers and liquid depositors. It has a maximum production speed of 40 packs a minute and can handle packaging that is 60-200mm wide and 50-250mm in length.

Horizontal sachet packing machines can produce sachets with widths ranging from 30-170 mm, achieving speeds of up to 200 sachets per minute. They fill and seal multiple sachet styles, including three- and four-sided sachets, various shapes, Euro-slot sachets, sachets with zippers, and more. Post-pack sachet filling machines integrate with labelling devices and filling systems, as well as post-machine collation and packing systems for enhanced flexibility and functionality.

Speedpack Hybrid is a compact FFS system available from Audion Elektro (W102). The advantage of Speedpack Hybrid lies in the system’s design, which allows for the use of tube film and bags-on-a-roll, eliminating the inconvenience of forming collars, back seaming, and the complex controls associated with traditional FFS systems.

All HFFS and VFFS systems are fed by pre-printed rollstock that goes into the system as a flat web before forming, filling, and sealing.

This could be Alox-Lyte™ from Jindal Films (D108), which is a transparent high barrier BOPP film that is vacuum coated on one side with aluminium oxide. To provide a transparent, high barrier solution to water vapor, oxygen, aromas, and mineral oils.

Roll film from Elite Flexibles (C50) can be used either as a mono web or as a laminate for HFFS or VFFS. They are available in different materials, such as PET, PE, PP, and laminated films, to meet specific packaging requirements. High barrier properties protect products from moisture, oxygen, and other contaminants and makes these films suitable for food and non-food applications suited for FFS, including snacks, chips, confectionery, frozen foods, dry foods, and personal care products.

snacks, chips, confectionery, frozen foods, dry foods, and personal care products.

St. Johns Packaging (P160) is a rollstock manufacturer that specialises in producing superior quality laminated and unlaminated custom roll stock packaging for various markets and purposes. Rollstock film is suited for industrial production and increasing packaging efficiency with HFFS and VFFS. Rollstock can be supplied unprinted or printed.

Mondi’s (E30) re/cycle range of heat sealable barrier papers are another option. These have very strong mechanical properties and can run on existing FFS/HFFS lines. re/cycle protects products by providing a moisture and water vapour barrier at the same time as being recyclable in most European wastepaper streams.

For those opting to use preformed pouches, such as those from Plastimak (P140) that can be supplied with or without a zipper, the AutoPack MH25 automatic premade pouch machine is designed to take premade pouches, fill them with product, then seal them with either a heat seal or some other form of seal, such as a zip or spout.

The machine is flexible, compact, and easy to use, with a maximum filling capacity of 35 packs per minute. It can be configured to handle different products and types of pouches.

This might include pouches made using the Bicor™ 25MR100 BOPP film from Jindal Films. 25MR100 is available as flat and stand-up premade pouches, as well as on a roll for FFS systems. This film is transparent and one-side treated, with improved heat stability. It is designed for flexible packaging applications where heat processes are used, such as hot filling, pasteurisation, sterilisation and retort.

Eco Pouch from National Flexible (E120) uses a film that has been specially developed to offer characteristics close to standard mixed polymer laminates that are more commonly used for stand-up pouches, coupled with the advantage of being able to be recycled. The special material can be used for 3 side seal formats, some VFFS applications, and, where required, a higher barrier version can be offered.

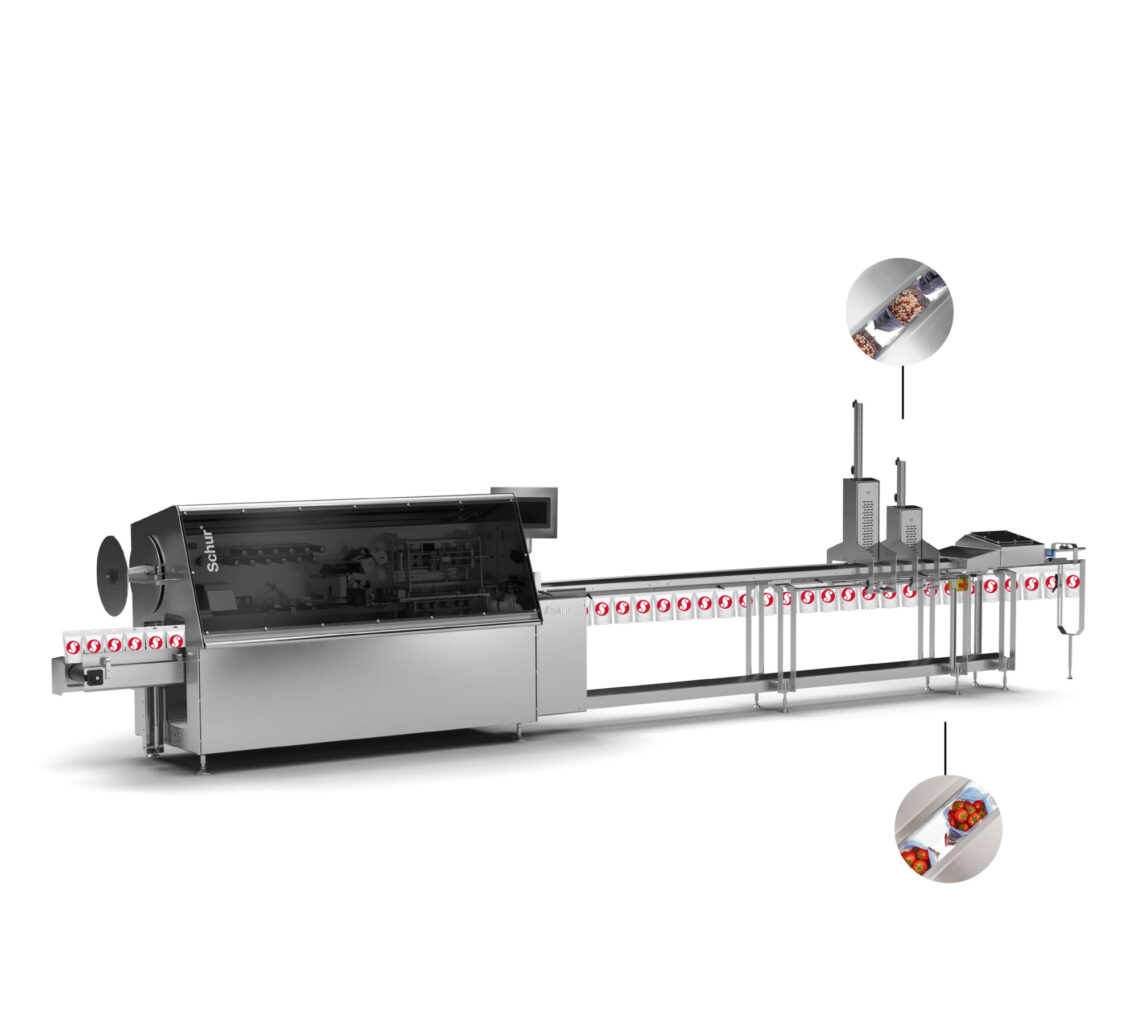

The Schur®Star (N130) Concept provides an efficient packing process, safe product processing, and bag constructions giving superior marketing opportunities. The system is described as ‘the world’s most flexible packaging solution’ and combines the Schur®Star Packaging Machine and premade Schur®Star Bags. Changeover between different bag constructions and sizes is done quickly and simply. The system can switch between manual, semi- or fully automatic filling, depending on the type and complexity of the products.

In all instances, complementary systems and equipment that support FFS processes are necessary, such as All-Fill’s (W114) augers.

An OEM version of the All-Fill Series 10 filling head can be integrated with HFFS and VFFS machines and other OEM equipment, while the Series 100 automatic inline auger filler permits fully automatic filling with no-tool container changeovers. It can fill a wide range of containers with fill weights from 1g up to more than 15kg. It is available in volumetric and gravimetric configurations with optional lift and vibration systems.

Durham Duplex (T132) specialises in the blades used in HFFS production. Zig-zag and straight knives are available standard and bespoke specifications. This includes progressive/straight cuts, partial or full zig-zag toothing, and tear notches.

Toothed knives are used in VFFS too and can be specified for the process, with different size teeth, alternate teeth, tiger teeth, a PVD coating, brass lugs, and more.

Friction and vacuum feeders are then used for offline coding of flat form packaging, including folded cartons, sleeves, blister cards, bags, and pouches. Savema friction and vacuum feeders, available through Martek Industries (T114), are used to feed products from stack to stack for coding with a choice of thermal transfer coder (TTO), inkjet printer, laser coder or label applicator.

All of these FFS solutions and more await the industry at Packaging Innovations & Empack 2026.

Join them by registering for your free ticket here, which grants you access to both days of Packaging Innovations & Empack 2026 when it takes place on 11 & 12 February next year at the NEC in Birmingham.

Share this article

Lorem ipsum dolor sit amet, consectetur adipiscing elit Lorem ipsum dolor sit amet, consectetur adipiscing elit

Latest news from Packaging Innovations & Empack

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.